Our Quality

management

Our production processes are highly automated - in some cases including automatic packaging in the transport packaging. This requires sophisticated quality management. Our production environment is the basis for a high level of safety and reliability. It is characterized by excellent hygiene conditions and comprehensive in-process control. A reusable box system that can be used directly in hygiene areas rounds off the process.

Microbiology

Our production halls are equipped with an air conditioning and ventilation system with class 7 supply air filters. The temperature is 24°C +/- 3°C.The resulting constant conditions have a positive effect on the microbiology. For this purpose, a separate GMP class E was introduced based on ISO class 9 of DIN EN ISO 14644-1.

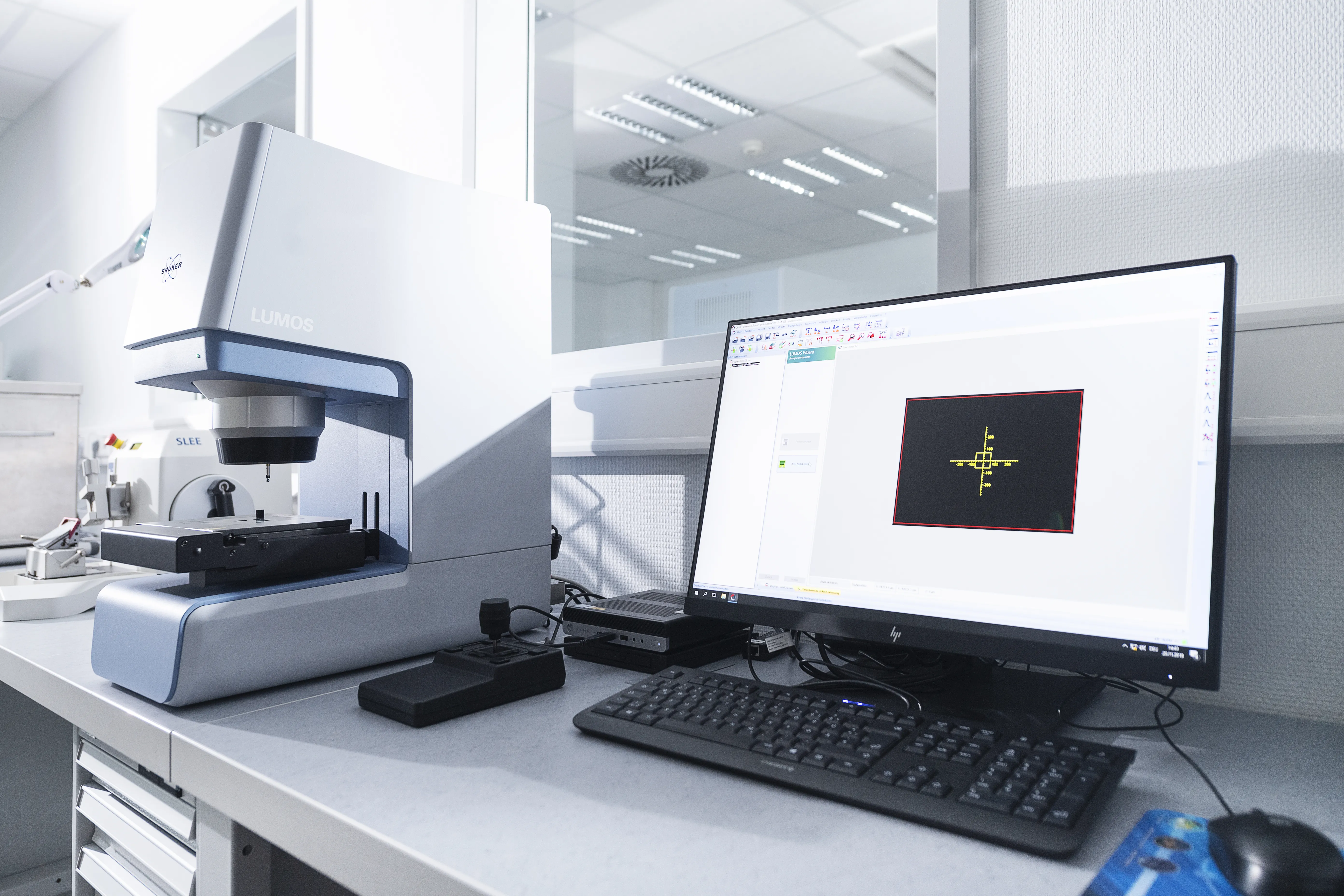

In-process-controlls

Our production facilities are equipped with camera systems. These systems perform attributive inspections on fully automated systems (automatic packaging) as well as the inspection of In-Mould-Labels (position, label type, etc.).

Reusable transport packaging

The components are packaged in reusable plastic packaging systems that are suitable for direct use in production.

Awarded and

certified.

certified.

CONTINUOUS QUALITY ASSURANCE.

From the start of component development to the release of the tool design, the highest demands are placed on technology and quality. In four qualification steps, the manufacturing process is tested and documented in detail across all phases of industrialization.

Design Qualification (DQ)

The requirements for the component are specified in the specifications and implemented by selecting a suitable tool concept.

Installation Qualification (IQ)

After the tool has been completed, this step checks whether it has been created in accordance with the DQ specifications. At the same time, tests are coordinated with the customer.

Operational Qualification (OQ)

This phase is used to find a safe process window. The process parameters are determined and documented with a view to their effects on the component by means of „DOE tests“ („Design of Experiments“). Within the scope of this „functional qualification“, both the performance capability of the tool and the machine capability are examined.

Performance Qualification (PQ)

In this qualification step, the process and its influencing parameters are known to the best of our knowledge. The process capability of the component is determined and assessed. On completion of the PQ, the component is released for series production.