Resource conservation and Climate protection in series with PÖPPELMANN blue®.

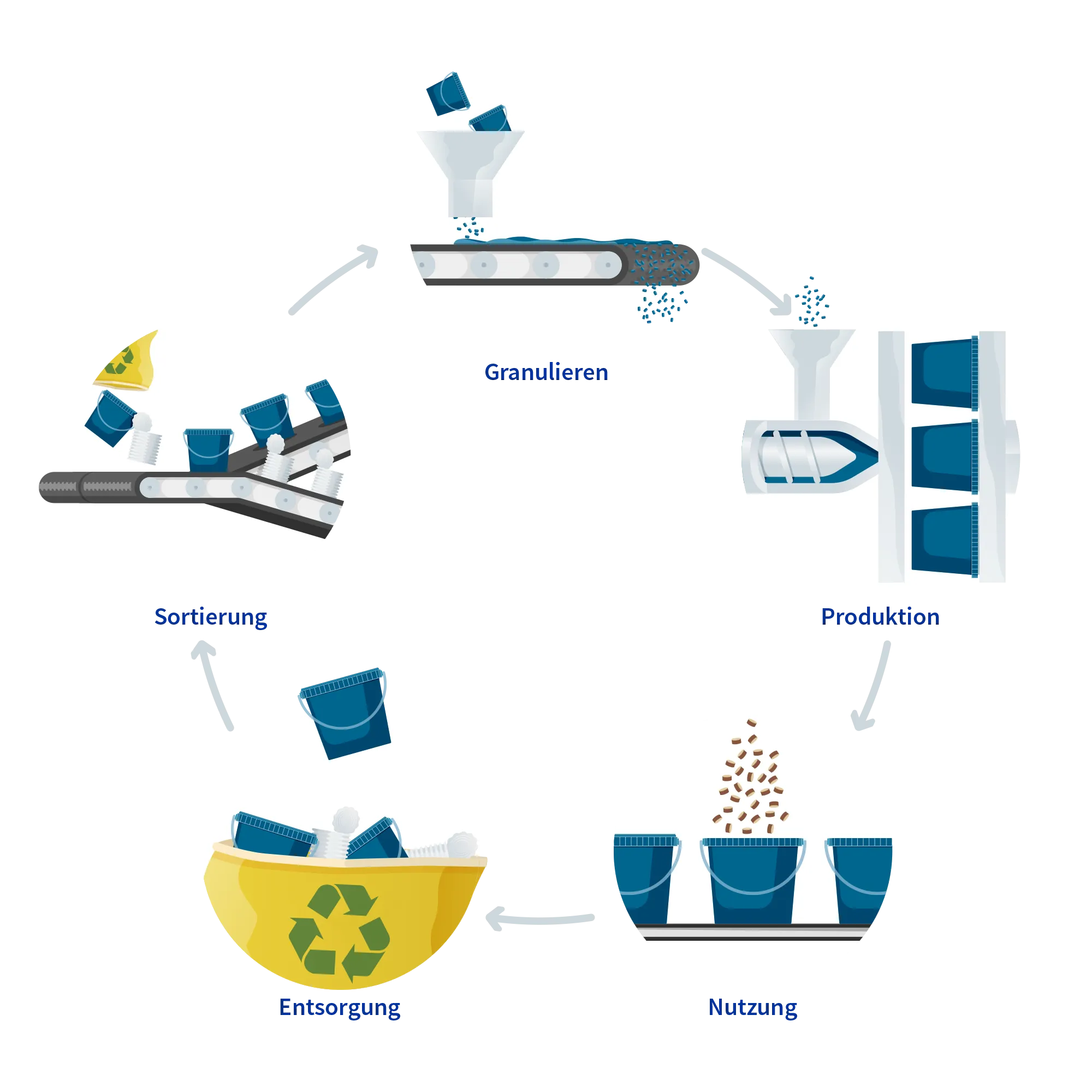

Plastic is a recyclable material that is all too often only used once. That's why we launched PÖPPELMANN blue®. Our company-wide initiative for resource conservation and climate protection. We focus primarily on the circular economy, in which plastic as a recyclable material is used as often as possible. Numerous series products made from resource-saving and therefore climate-friendly post-consumer recyclates are now in circulation in various markets - including our packaging made from recyclate. This consists of recyclates obtained from packaging waste from the Dual System. After use, these items are maximally recyclable.

We will be glad to check what amount of post-consumer recyclate your product can be made from.

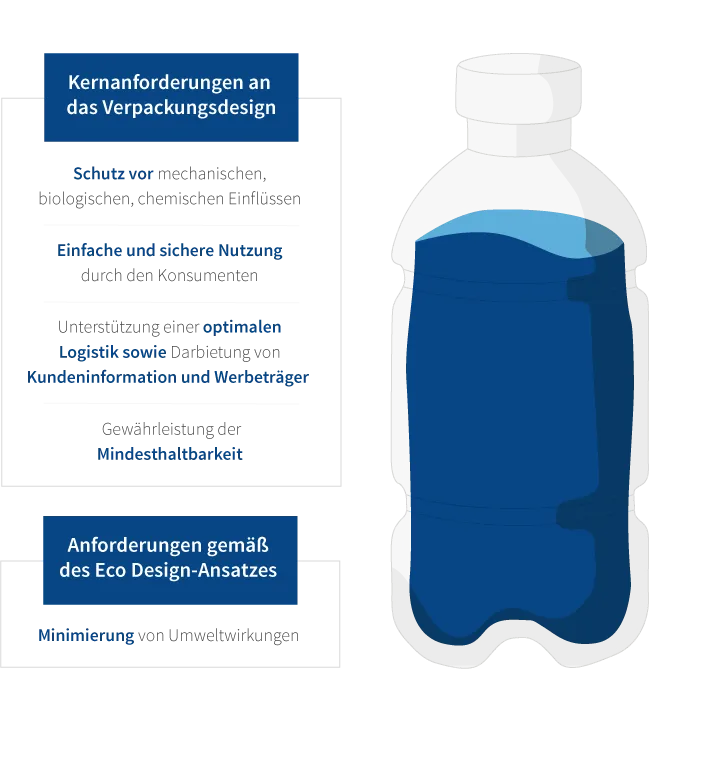

Product development according to the eco-design principle.

The environmental impact of a product along its entire life cycle is taken into account here and kept as low as possible. "Reduce, Reuse, Recycle" creates article concepts that reduce the use of materials and energy during production without impairing the functionality of the product, that focus on multiple use where possible and, at best, completely close the material cycle through the use of recyclates.

Reduce

We reduce the use of materials through resource-saving concepts and efficient production processes. With T-IML, we reduce the use of materials to a minimum.

Reuse

We develop reusable packaging for the catering and hospitality industry. Our reusable popcorn cups are a real alternative to disposable paper containers.

Recycle

We close recycling loops. Discover our PÖPPELMANN blue® initiative and our packaging made from post-consumer recycled material.

Initiative PÖPPELMANN blue®.

Environmental and climate protection are becoming increasingly important for consumers. Nevertheless, the modern lifestyle is a challenge for packaging designers and the environment: Europeans produce 25 million tons of plastic waste every year. This is why we, as plastics processors, see it as our duty to design products and processes that are as environmentally friendly as possible. The aim is for the plastic in our packaging to come directly from the Yellow Bag and end up there again. This closes the raw material cycle completely. We call this action PÖPPELMANN blue®.

We are setting new standards in our markets and are one of the leading processors of PCR-PP in Germany.

Since the start of the PÖPPELMANN blue® initiative in 2018, Pöppelmann has brought products into series production in every division that are made from post-consumer recyclates (PCR) from used packaging (Yellow Bag or Yellow Bin).

What do we mean by

future-proof packaging?

future-proof packaging?

The EU Packaging & Packaging Waste Regulation (PPWR) sets out the framework conditions for how packaging should be designed in the future. Unnecessary packaging and packaging waste should be reduced and reusable systems and recycling should be promoted. In our opinion, plastic packaging meets precisely these requirements, as plastic is more efficient than alternative materials.

Mainly less plastic?

Plastic is more efficient than alternative materials.

On the

The wrong track?

PPWR is driving deforestation and the growth of mountains of waste.

Minimum recyclate usage?

100% in unregulated sectors (e.g. nonfood) creates incentives for investment in mechanical recycling.

Design For

Recycling?

Recyclability and the use of recyclates are the basis for a functioning circular economy.