lab &

Diagnostics

Diagnostics

For the laboratory & diagnostics sector, stability, media resistance, cleanliness, hygiene and documentation are our top priorities. For this reason, we offer customized component development, moldmaking and cleanroom production according to the guidelines of GMP (Good Manufacturing Practice) with corresponding documentation. The articles are manufactured under cleanroom conditions to DIN EN ISO Class 7, GMP Standard C. With our own mold center, state-of-the-art injection molding machines, individual assembly techniques and fully automated cleanroom production, we are ready to take on challenges and explore new paths together with you.

Disposables

for molecular diagnostics

Filter plates

for molecular diagnostics

Reagentbox

for molecular diagnostics

Spin Column

for molecular diagnostics

Vessels

for sample purification

Lab vessels

with and without lid

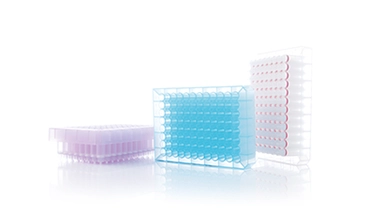

Microtiter Plate

96 well

Rack

for centrifuges

Individual solutions

Customer-specific development, contract manufacturing or resource-saving optimizations. We look forward to discussing your application.

What do we mean by continuous quality assurance?

From the start of component development to the release of the mold design, the highest demands are placed on technology and quality. In four qualification steps, the manufacturing process is tested and documented in detail throughout all phases of industrialization:

- Design Qualification (DQ)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)