Complete switch to recycling protection solutions

Nepomuk Walther-Otto, DELTA Energy Systems GmbH

>Society and the economy are on the brink of change and today need new solutions to reduce the need for fossil or primary resources and to protect the climate.

We are taking responsibility - also for future generations and are making protective elements made from recycled plastic the new standard with immediate effect. Accordingly, we have gradually converted our standard range to our sustainable alternatives made from post-consumer recyclate and expanded it for our customers by a further 2,000 items in yellow, blue and many other colours.

Here we explain what sustainable plastic is, what exactly the changeover means and how you can benefit from the changeover.

contain our most sustainable protective elements, which therefore also conserve up to 100% of resources. These items emit up to 45% less CO2 than new products and can be fully returned to the material cycle after use. Our articles with such a high PCR content have been labelled with the Blue Angel environmental seal since 2020.

Pipe protection cap - GPN 250, PCR-PE, blue

Screw plugs - GPN 700 made of PCR-PEHD

is a mixture of predominantly post-consumer recycled material (PCR) and virgin material, which means that the protective elements have a significantly lower CO2 impact compared to the virgin material variant and also save fossil resources. Thanks to the proportion of virgin material, we can produce the items in various familiar colours despite the high level of sustainability.

Protective caps - GPN 200 type A, PCR-PE / PE-LD

Flexible grip caps - GPN 211, PCR-TPE

Would you also like to purchase protective elements made from sustainable plastic now?

Nepomuk Walther-Otto, DELTA Energy Systems GmbH

>Johnnes Ebel, Eckerle Technologies GmbH

>Proven protective elements made from post-consumer recyclate

Further sustainable protective elementsConserving resources.

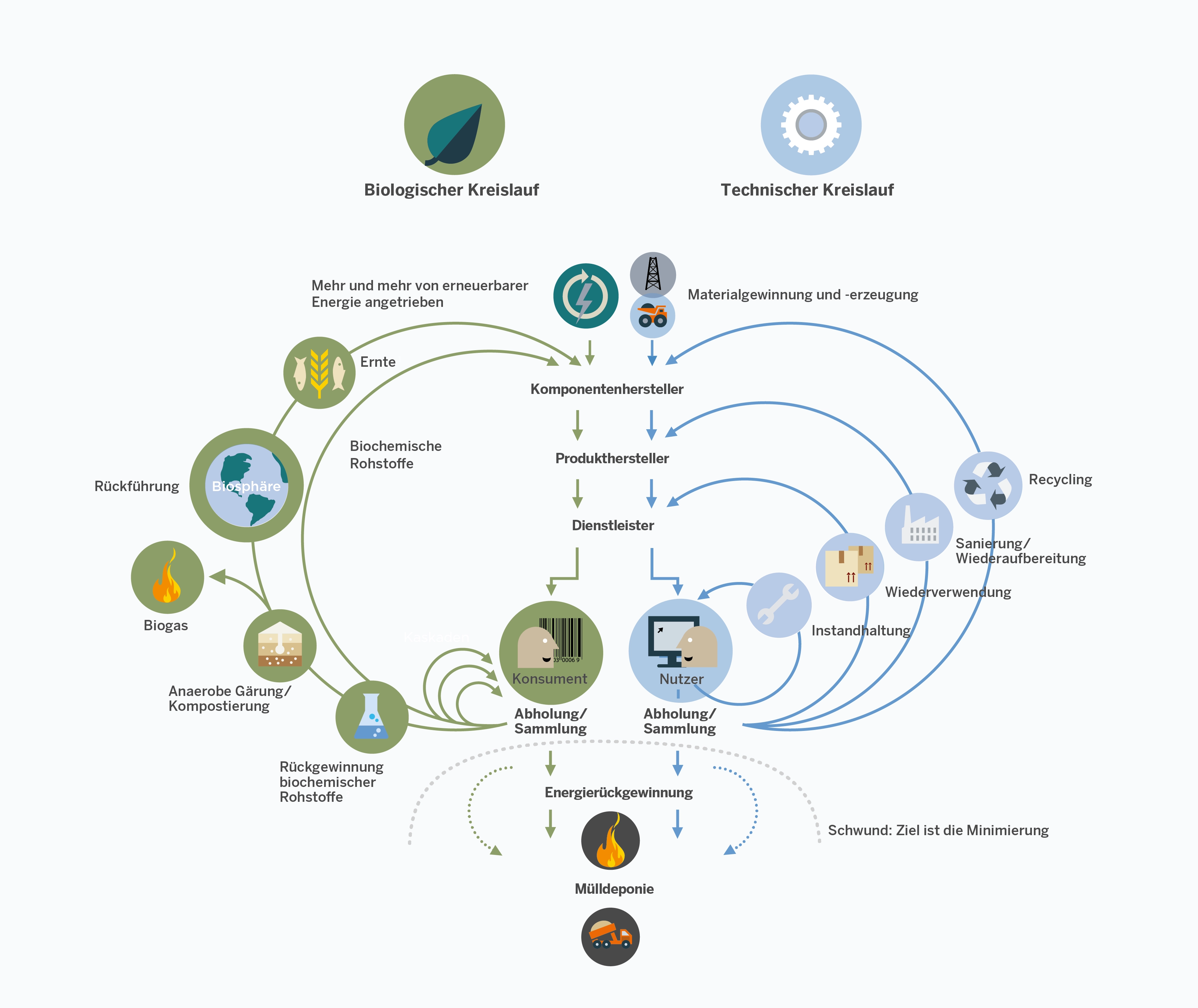

The future belongs to the circular economy.

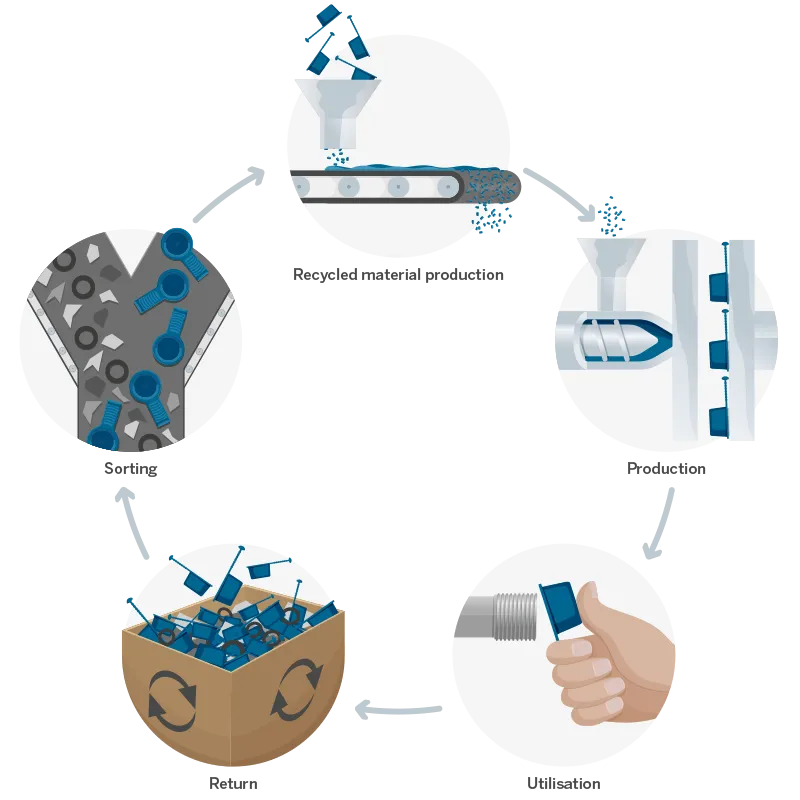

Recyclate production.

Used plastic products that have gone through a life cycle, such as our caps and plugs, are processed into recyclate.

Production.

The recyclate produced is used for the production of new caps and plugs.

Utilisation.

The recycled plastic caps and plastic plugs are then used to protect components.

Return.

After use, the items can be disposed of via an external service provider or directly via Pöppelmann.

Sorting.

The caps and plugs are then sorted by type of plastic and can be reused for the production of recyclate.

Sustainability all along the line.

To protect the climate and conserve resources, we not only produce resource-saving protective elements, we are also increasingly focussing on sustainable alternatives throughout the company and especially in our supply chain.

From the procurement ...

Right from the procurement stage, we rely on recyclates made from recycled plastic, which are then added back into the cycle. Here we benefit from years of experience from our own compounding and can therefore have a positive influence on the quality of the post-consumer recyclate. The procurement process is accompanied by our quality assurance, for example during the incoming goods inspection.

... about production ...

Since the introduction of our environmental management system in 1996, we have continuously improved our energy efficiency in particular through focussed energy monitoring, the introduction of heat recovery systems and the procurement of energy-efficient machines. Since 2021, we have relied on a high proportion of green electricity in our energy mix for our production, thus significantly reducing our carbon footprint once again. In addition, leaner production processes have been integrated, which fundamentally reduce our reject rate and ensure more effective material utilisation through recycling mills directly on the machine.

... right through to recycling.

All PCR articles manufactured by us are recyclable. To do this, you can simply contact a recycling company in your region or us to close the material cycle. This tried-and-tested process not only reduces your company's CO2 footprint, but also conserves natural resources and protects the climate.

Contact us

Please use the following form to get in touch with us. We are at your disposal!

We are converting a very large part of our catalogue range to more resource-efficient materials with a lower carbon footprint - and in many colours, including yellow. Specifically, the material is changing from a virgin plastic to a sustainable recycled plastic. This is a 100% post-consumer recyclate or recycled blend. You will receive the parts in the usual Pöppelmann quality, only with a lower CO2 footprint and with fewer resources. For coloured catalogue parts, we always use the same basic colours as for new goods, so that there are no or only slight variations in colour. So if you have previously received yellow parts, you will continue to receive parts in yellow. Natural-coloured products are changed to blue in order to achieve an appealing look.

The new standard

As a rule, all catalogue parts made of PE-LD, PE-HD, TPE, EVA can be converted.

If your internal processes require it, you are welcome to change your material numbers. However, this is not necessary for us, i.e. you are welcome to continue using your existing material numbers. We will add the PCR material to our article descriptions and send you the new Pöppelmann article numbers by order confirmation - you can then transfer these to your system. Only the last two or four digits of our 11-digit article numbers will change.

Taking responsibility for the future together.

First and foremost, we are working together to conserve resources and protect the climate. You will receive our protective elements in the usual Pöppelmann quality, but more sustainably than before. In this way, you can contribute to more resource conservation, waste avoidance and climate protection without great effort and thus fulfil the corresponding requirements from the industry for recycling management, recyclate content and climate protection! OEMs are already demanding the use of PCR. This can also contribute to your own sustainability goals. We also expect EU and national legislation regarding recycling quota requirements in the near future. You would then have already fulfilled these requirements for the products in question.

In order to make the switch to the new, resource-saving items not only simple but also cost-neutral, the prices remain the same compared to the previously purchased new products. All other conditions will also remain unchanged. In the long term, it can be assumed that prices and conditions for new items will increase significantly, as they will only be purchased by very few customers.

The protective elements made from recycled material are generally available from stock, just as you are used to from our previous articles.

Switching to protective elements made from 100% post-consumer recyclate or the recycling mix offers many advantages: you already fulfil existing and future industry and legislative requirements for recycling quotas, etc. You can also use your own sustainability targets and reports. You can also use the changeover for your own sustainability targets and reports. And most importantly, for every kilo of recycled material, you save up to one kilo of virgin material that has to be produced from crude oil, thus helping to conserve fossil resources and reduce greenhouse gas emissions. Catalogue parts made from virgin material will probably only be used very sporadically in the future, which will then also have an impact on conditions and delivery times. There are therefore many arguments in favour of switching to our sustainable protective elements. However, if there are reasons why it is not possible for you to switch to a recycled material, please contact us.

Test the usual Pöppelmann quality free of charge.

You can of course receive free samples as usual. As not all items in the recycling material are expected to be in stock immediately during the gradual changeover, we may only be able to send you a selection of samples.

Simply click on the button and find the items you want.

Post-consumer recyclate.

A recyclate is obtained by recycling used plastic products that have already gone through a complete product life cycle. Our 100% post-consumer recyclate consists entirely of recycled material and thus conserves up to 100% of resources. (PCR-PE, PCR-PE-HD, PCR-PP)

A blend, described with the English word ‘blend’, consists of PCR and virgin material. (PCR-PE / PE-LD, PCR-TPE, PCR-TPE (EVA eq.))

Virgin material is obtained from fossil raw materials. (PE-LD, PE-LLD)

Protection in the usual Pöppelmann quality.

It goes without saying that we have extensively tested both our 100% post-consumer recyclate and our new recycling mix for their qualitative properties, particularly with regard to the dimensional accuracy and functionality of our catalog items in accordance with the product specifications given in the catalog. This is done, among other things, through incoming goods inspections of the raw material and through tests during production. The materials used have already proven themselves in a large number of other Pöppelmann KAPSTO® protective elements. We are convinced that this high quality will fully meet your expectations.

As a rule, the properties required for the application are almost identical. In the event of deviations, it must be checked whether these have an influence on the application. An overview of the technical properties of all the materials we use - both PCR and virgin material - can be found in our materials table, or you can contact us directly.

Certified cleanliness according to ISO9001.

We see no difference when it comes to cleanliness. Our protective elements made from the new recycled material or the recycled mix are manufactured under the same ISO9001-certified production conditions as protective elements made from virgin material. Occasional discoloration, streaks or dark spots are possible with both protective elements made from virgin material and recycled material and cannot be avoided due to the manufacturing process - there is therefore no difference in terms of cleanliness. This also has no effect on the number of organic or inorganic foreign particles. If increased technical cleanliness is required for your application, we can manufacture our protective elements in our in-house clean room.

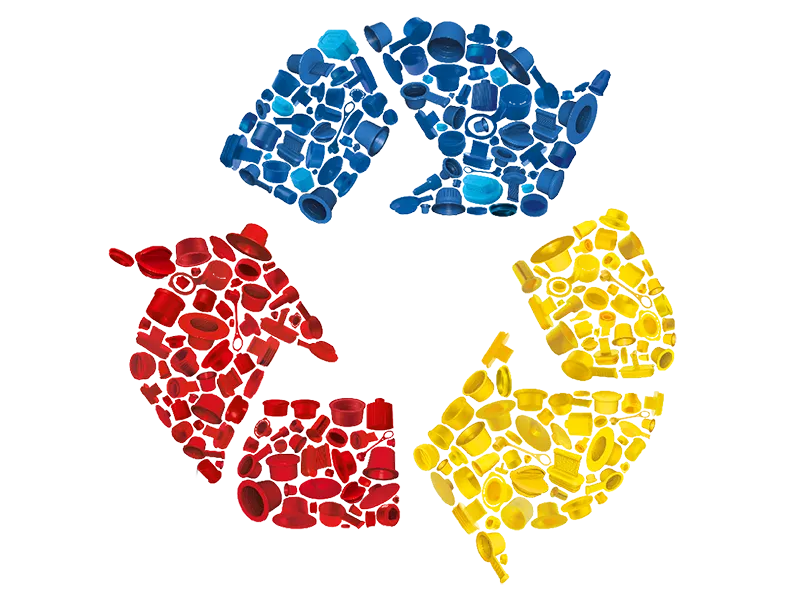

Sustainable protective elements in a wide range of colors.

All colored catalog parts made of PE-LD, TPE and EVA (e.g. yellow, green, red, black) are converted to a recycled mixture of PCR and virgin material and are always produced in the same basic color as the virgin material, so that there are no or only slight deviations in the color tone.

Natural-colored catalog parts made of PE-LD and colored catalog parts made of PE-HD are converted to a 100% PCR and to the color blue. This color corresponds approximately to the RAL shade of traffic blue.

100% recyclable.

After use, the used protective elements should be disposed of properly. This can be done via a local recycling company, for example. We would also be happy to talk to you about the possibility of returning them to Pöppelmann. In many cases, we can create a closed material cycle together and save important resources.

Color deviation due to high standard.

Blue offers a significantly better appearance compared to natural with the PCR materials used. Catalog parts in natural-colored recycled PCR plastic would be comparatively dark and not or significantly less translucent than catalog parts made from virgin material. We also opted for the color blue to create a high recognition value for the protective elements made of 100% post-consumer recycled material, awarded the Blue Angel, and to deliberately differentiate them from more common colors such as yellow, red or natural. Furthermore, the color blue is now even required by some car manufacturers as a standard color for protective elements made of PE-LD and PE-HD in order to enable clear sorting by color and thus better recycling.

All standard documents for the protective elements in the recycling materials are available as usual. You can view or download the material data sheet and a safety data sheet directly via the button. If further documents are required, we will be happy to check the feasibility and inform you about the costs to be calculated.

We are meticulously evaluating the topic of bioplastics throughout the company. Current findings confirm that the recycled plastics we use save more natural resources than bioplastics and are more climate-friendly due to the higher CO2 savings.

Bio-based plastics can be a sensible alternative if suitable recycled plastics are not available. In many cases, however, bio-based plastics must be evaluated critically, e.g. if the raw materials for them grow in monocultures such as sugar cane, or if they compete with food production. According to BUND, biodegradable plastics are a waste of energy and resources. In industrial composting plants, these are considered impurities.

That is why we prefer post-consumer recyclates. In this way, we promote the circular economy and keep the valuable material plastic in the cycle.

On request, catalog parts can be converted from standard material to a PCR material. In principle, it is also possible to convert customer-specific special parts to a PCR. So if you would like to convert catalog parts or special parts, please contact us and we will check what is possible.

We are also working on developing sustainable variants for other materials to conserve even more resources.